Vinyl acetate (VAc), inozivikanwawo sevinyl acetate kana vinyl acetate, imvura isina ruvara inopenya pane yakajairika tembiricha uye kumanikidzwa, ine molecular formula yeC4H6O2 uye imwe hama molecular huremu hwe86.9.VAc, seimwe yeanonyanya kushandiswa maindasitiri organic mbishi zvinhu munyika, inogona kugadzira zvinobva senge polyvinyl acetate resin (PVAc), polyvinyl doro (PVA), uye polyacrylonitrile (PAN) kuburikidza nekuzvimiririra polymerization kana copolymerization nemamwe mamonmers.Izvi zvinobva zvashandiswa zvakanyanya mukuvaka, machira, michina, mishonga, nekuvandudza ivhu.Nekuda kwekukurumidza kukura kweiyo terminal indasitiri mumakore achangopfuura, kugadzirwa kwevinyl acetate kwakaratidza maitiro ekuwedzera gore negore, pamwe nekuzara kwekugadzirwa kwevinyl acetate kusvika 1970kt muna 2018. Parizvino, nekuda kwesimba rezvinhu zvakasvibiswa uye maitiro, nzira dzekugadzira dzevinyl acetate dzinonyanya kusanganisira acetylene nzira uye ethylene nzira.

1, Acetylene process

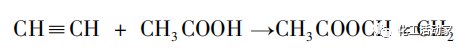

Muna 1912, F. Klatte, wekuCanada, akatanga kuwana vinyl acetate ichishandisa yakawandisa acetylene uye acetic acid pasi pekumanikidzwa kwemhepo, patembiricha kubva pa60 kusvika ku100 ℃, uye kushandisa mercury munyu sezvinokonzera.Muna 1921, Kambani yeGerman CEI yakagadzira tekinoroji yevapor phase synthesis yevinyl acetate kubva kuacetylene uye acetic acid.Kubva ipapo, vaongorori vanobva kunyika dzakasiyana siyana vakaramba vachikwenenzvera maitiro uye mamiriro eiyo synthesis yevinyl acetate kubva acetylene.Muna 1928, Hoechst Kambani yekuGermany yakagadzira 12 kt/a vinyl acetate yekugadzira unit, ichiona maindasitiri makuru ekugadzirwa kwevinyl acetate.Iyo equation yekugadzira vinyl acetate nenzira yeacetylene ndeiyi inotevera:

Main reaction:

Acetylene nzira yakakamurwa kuita yemvura chikamu nzira uye gasi chikamu nzira.

Iyo reactant phase state yeacetylene fluid chikamu nzira imvura, uye reactor itangi rekuita rine mudziyo unomutsa.Nekuda kwekukanganisa kweiyo fluid chikamu nzira senge yakaderera selectivity uye akawanda-zvigadzirwa, iyi nzira yakatsiviwa neacetylene gasi chikamu nzira parizvino.

Zvinoenderana neakasiyana masosi ekugadzirira gasi acetylene, iyo acetylene gasi chikamu nzira inogona kukamurwa kuita gasi rechisikigo acetylene Borden nzira uye carbide acetylene Wacker nzira.

Iyo Borden process inoshandisa acetic acid seye adsorbent, iyo inovandudza zvakanyanya mwero wekushandiswa kweacetylene.Nekudaro, iyi nzira yehunyanzvi yakaoma uye inoda kudhura kwakanyanya, saka nzira iyi inotora mukana munzvimbo dzakapfuma mune zvakasikwa gasi zviwanikwa.

Maitiro eWacker anoshandisa acetylene uye acetic acid inogadzirwa kubva kucalcium carbide seyakagadzirwa, ichishandisa catalyst ine activated kabhoni semutakuri uye zinc acetate sechinhu chinoshanda, kugadzira VAc pasi pekumanikidzwa kwemhepo uye kuita tembiricha ye170 ~ 230 ℃.Iyo tekinoroji tekinoroji iri nyore uye ine mutengo wakaderera wekugadzira, asi pane zvikanganiso sekurasikirwa kuri nyore kwezvinhu zvinokonzeresa zvinoshanda, kusagadzikana kwakashata, kushandiswa kwesimba kwakanyanya, uye kusvibiswa kukuru.

2, Ethylene process

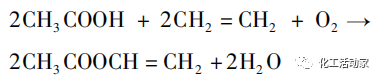

Ethylene, okisijeni, uye glacial acetic acid zvinhu zvitatu zvinoshandiswa mu ethylene synthesis yevinyl acetate process.Chinhu chikuru chinoshanda checatalyst chinowanzova cheboka rechisere noble metal element, iyo inobatwa pane imwe reaction tembiricha uye kumanikidza.Mushure mekugadzirisa kunotevera, iyo yakanangwa chigadzirwa vinyl acetate inozopedzisira yawanikwa.Iyo reaction equation ndeiyi inotevera:

Main reaction:

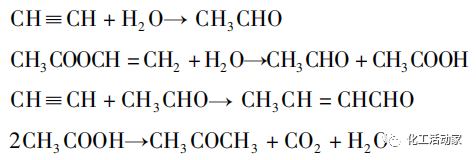

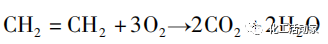

Side effects:

Iyo ethylene vapor phase process yakatanga kugadzirwa neBayer Corporation uye yakaiswa muindasitiri yekugadzira vinyl acetate muna 1968. Mitsetse yekugadzira yakavambwa muHearst neBayer Corporation muGermany neNational Distillers Corporation muUnited States, zvichiteerana.Iyo inonyanya kurongedzerwa palladium kana goridhe pazvitsigiro zvinodzivirira acid, senge silica gel mabheji ane radius ye4-5mm, uye nekuwedzera kweimwe huwandu hwe potassium acetate, iyo inogona kuvandudza chiitiko uye kusarudzwa kweiyo catalyst.Maitiro ekugadzirwa kwevinyl acetate uchishandisa ethylene vapor chikamu USI nzira yakafanana neBayer nzira, uye yakakamurwa kuita zvikamu zviviri: synthesis uye distillation.Nzira yeUSI yakawana kushandiswa kwemaindastiri muna 1969. Zvishandiso zvinoshanda zvechigadziridzo zvinonyanya palladium neplatinum, uye mubatsiri we potassium acetate, iyo inotsigirwa pane alumina carrier.Mamiriro ekuita ari munyoro uye iyo catalyst ine hupenyu hurefu hwesevhisi, asi goho renguva-yakaderera.Kuenzaniswa neacetylene nzira, iyo ethylene vapor chikamu nzira yakagadziridzwa zvakanyanya mune tekinoroji, uye macatalysts anoshandiswa muethylene nzira yakaramba ichivandudza mukuita uye kusarudza.Nekudaro, iyo reaction kinetics uye deactivation mechanism ichiri kuda kuongororwa.

Kugadzirwa kwevinyl acetate uchishandisa ethylene nzira inoshandisa tubular fixed bed reactor yakazadzwa necatalyst.Iyo gasi rekudya rinopinda mureactor kubva kumusoro, uye kana richinge rabata mubhedha unokonzeresa, zvinokonzeresa zvinobatika zvinoitika kuburitsa chinonangwa chigadzirwa vinyl acetate uye chidiki chidiki che-chigadzirwa kabhoni dhaidhi.Nekuda kweiyo exothermic maitiro ekuita, mvura yakamanikidzwa inounzwa mugoko reiyo reactor kuti ibvise kupisa kwekuita nekushandisa vaporization yemvura.

Kuenzaniswa neacetylene nzira, iyo ethylene nzira ine maitiro eiyo compact mudziyo dhizaini, yakakura kubuda, yakaderera simba rekushandisa, uye yakaderera kusvibiswa, uye mutengo wayo wechigadzirwa wakaderera pane iyo yeacetylene nzira.Hunhu hwechigadzirwa hwakakwirira, uye corrosion mamiriro haana kukomba.Nokudaro, nzira ye ethylene zvishoma nezvishoma yakatsiva nzira yeacetylene mushure memakore ekuma1970.Zvinoenderana nehuwandu husina kukwana, inosvika makumi manomwe muzana yeVAc inogadzirwa ne ethylene nzira munyika yave nzira huru yekugadzira VAc.

Parizvino, tekinoroji yepamusoro yekugadzira VAc munyika ndeyeBP's Leap process uye Celanese's Vantage process.Kuenzaniswa neyakagadzika mubhedha gasi chikamu ethylene process, aya maviri maitirwo matekinoroji akavandudza zvakanyanya reactor uye catalyst papakati peyuniti, kuvandudza hupfumi uye kuchengetedzeka kwekushanda kweyuniti.

Celanese yakagadzira mutsva wakagadziriswa mubhedha Vantage maitiro ekugadzirisa matambudziko ekusaenzana kwebhedha yekugovera mubhedha uye yakaderera ethylene imwe nzira kutendeuka mumubhedha wakagadziriswa.Iyo reactor inoshandiswa mukuita iyi ichiri mubhedha wakagadziriswa, asi kuvandudzwa kwakakosha kwakaitwa kune catalyst system, uye ethylene yekudzoreredza michina yakawedzerwa muswe gasi, kukunda zvikanganiso zvechinyakare zvakagadziriswa mubhedha maitiro.Iyo goho yechigadzirwa vinyl acetate yakanyanya kukwirira kupfuura yemidziyo yakafanana.Iyo process catalyst inoshandisa platinum sechinhu chikuru chinoshanda, silica gel secatalyst carrier, sodium citrate sechinhu chinoderedza, uye mamwe masimbi anobatsira akadai selanthanide isingawanzo pasi zvinhu zvakaita sepraseodymium uye neodymium.Kuenzaniswa nezvinokonzeresa zvechinyakare, iyo selectivity, chiitiko, uye nzvimbo-yenguva goho yecatalyst inovandudzwa.

BP Amoco yakagadzira mubhedha we ethylene gasi phase process, inozivikanwawo seLeap Process process, uye yakavaka 250 kt/a fluidized bed unit muHull, England.Kushandisa nzira iyi kubudisa vinyl acetate kunogona kuderedza mari yekugadzira ne30%, uye nguva yenguva yegoho ye catalyst (1858-2744 g/(L · h-1)) yakakwirira zvikuru kupfuura iyo yemubhedha wakagadziriswa (700). -1200 g/(L · h-1)).

Iyo LeapProcess maitiro anoshandisa yakanyungudika mubhedha reactor kekutanga, ine zvinotevera zvakanaka zvichienzaniswa neyakagadziriswa mubhedha reactor:

1) Mumubhedha wemvura inoyerera, iyo catalyst inoramba ichiita uye yakafanana yakasanganiswa, zvichibva zvaita kuti yunifomu iparadzirwe yemusimudziri uye kuve nechokwadi chekusangana kwakafanana kweanosimudzira muiyo reactor.

2) Iyo fluidized bed reactor inogona kuramba ichitsiva iyo deactivated catalyst ine nyowani catalyst pasi pemamiriro ekushanda.

3) The fluidized bed reaction tembiricha inogara iripo, ichideredza catalyst deactivation nekuda kwekupisa kwenzvimbo, nekudaro kuwedzera hupenyu hwesevhisi yecatalyst.

4) Iyo nzira yekubvisa kupisa inoshandiswa muiyo fluidized bed reactor inorerutsa iyo reactor chimiro uye inoderedza huwandu hwayo.Mune mamwe mazwi, dhizaini imwe chete reactor inogona kushandiswa kune yakakura-yakakura kuisirwa kemikari, ichivandudza zvakanyanya kunaka kwechishandiso.

Nguva yekutumira: Mar-17-2023